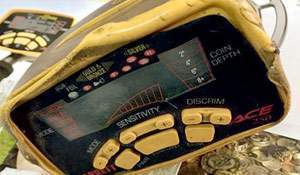

I bought my Garrett ACE 250 eight years ago, and have never regretted this choice. It is simple, reliable and, most significantly, always gets finds. However, the ACE 250, like any other metal detector, has its problems.

Armrest

The Garrett ACE 250 has a rather weak armrest that can be easily broken down, hit or pressed during transport, but most commonly it breaks down when the large-sized coils are used (this problem is most acute with large coils). It makes no sense to repair the broken armrest, it will still break down again, you see. The solution is to make a home-made armrest, for example, of a plastic water-pipe or to buy a new one.

For the ACE 250 metal armrests can be found for sale. They are reliable, but noticeably heavier, however, and apt to corrosion with the lapse of time.

Middle shaft

Loose connections of the middle shaft. If the detector is used actively, the shaft attachment point wears out in as little as a year. The problem is minor and, in fact, doesn’t affect anything. There is simply rattling in shafts when swinging the detector. You can try to restore it by adding a sealing.

But the most effective way is to use the locking collars. For example, these ones of the Garrett AT PRO shaft are suitable for the ACE 250.

Bolt

The coil attachment bolt of the АСЕ 250 often breaks down. This problem is caused by wear and tear of rubber washers at the coil attachment point as it takes more effort to tighten the bolt (otherwise the coil will hang loose).

Some time the bolt doesn’t sustain under strain and breaks (it is plastic). Instead of the native one, you can use any other plastic bolt with a nut that can be inserted through the holes of a lower shaft and a search coil. For example, a plumbing or a construction toys (plastic) one.

Search coil

The original 6.5?9 PROformance search coil is rather weak on detection depth and has a small scanned area (however, it has a perfect pinpoint and is stable at full sensitivity). To increase detection depth of the Garrett ACE 250 metal detector, the standard coil can be replaced.

For example, with a larger sized and DD type coil. It will increase the detection depth and stability in mineralized soil. It should be taken into account that use of large coils reduces the detection accuracy in pinpoint mode, there are also load on the shaft and higher than usual power consumption.

Volume control

The Garrett ACE 250 metal detector has no volume control. It is not considered to be a problem, but sometimes it is inconvenient as a sound response of the device is rather loud. The simplest way to reduce volume is to glue up the speaker holes on the housing (with any duct tape) or to use headphones with adjustable volume. If you wear headphones, the response is heard better, plus batteries are saved.

When the Garrett ACE 250 batteries run down, the detector gives false signals. At first you can put them down for a positive response without understanding what is happening. It is enough to raise the coil in the air (false responses will also be there) and it will become clear that it’s time to replace the batteries of the detector. Furthermore, when the power supply is less than a half, the ACE 250 starts to lose a bit of detection depth (minus 1-2 centimeters).

All about the Garrett ACE 250 is collected here (news, tests, comparisons with other devices, different reviews and opinions). Plus, on Knowledgebase pages there is additional information you should know before buying the Garrett ACE 250. The experience of others will help you save your time and money. Happy hunting to everyone!

It can be still added on coil protection (that is absent in standard equipment)… The work surface of the АСЕ 250 coil receives scratches, chips and cracks during searches.

As a result this may lead to a coil breakdown. For example, if moisture penetrates inside through a crack. When possible, it is better to use the coil with a plastic cover. It should be taken into account that any coil protection increases its total weight. Moisture and dust may penetrate under the cover that may cause false signals. But all the detectors are subject to this.

I will add. With the lapse of time, a foam hand grip of my Garrett ACE 250 started spinning and moving around on the shaft. This one can be glued, but it’s a little problem, I usually don’t notice it in practice.

hi,just wondering if if you shed any light with my garret problem,a worls fine but the built in pin pointer makes the sound but shows no black bars,thanks in advance

I’ve had my Ace 250 for over 5 years, and it still looks and works like new. I’vd found more Gold and other valueable items than with any of the 18 detectors that I’ve owned thru the years. Some detectorists don’t know how to take good care of their detectors, mistreat them and break them. Nothing wrong with the awesome Ace detectors, more like “user abuse problem”.

So there a good metal detector to get then